-

Portable Hardness Tester

-

Portable Leeb Hardness Tester

-

Hardness Tester

-

Ultrasonic Thickness Gauge

-

Concrete Test Hammer

-

Brinell Hardness Testing

-

Rockwell Hardness Tester

-

Vickers Hardness Tester

-

Gloss Meter

-

Color Difference Meter

-

Metallurgical Microscope

-

Surface Roughness Tester

-

Ultrasonic Flaw Detector

-

Portable Vibration Meter

-

Paul FrameThank you very much for all your help regarding the SADT Concrete Hammer and hardness tester which are working well and we are very pleased with it.

Paul FrameThank you very much for all your help regarding the SADT Concrete Hammer and hardness tester which are working well and we are very pleased with it.

Impact Device Portable Hardness Tester Metal Hardness Tester For Petro Chemistry

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Warranty | 12 Months | Key Words | Metal Hardness Tester |

|---|---|---|---|

| Impact Direction | Auto Impact Direction With 360 Degree | Product Name | HBC Portable Hammering Brinell Hardness Tester |

| Highlight | leeb hardness tester,integrated hardness tester |

||

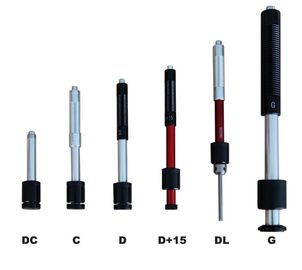

Impact device/Probe for IMPACT DEVICE

Leeb hardness tester

Various impact devices includes analog impact device, digital impact device, wireless impact device, universal impact device and unique reading probe, they are designed for Leeb hardness testers, which make the testers suitable for testing the hardness of all metals. They are widely used in the industry of power, petro chemistry, air space, vehicle, machine and so on.

Specifications

| Impact Device (Probe) | Description |

| D | Universal standard unit for majority of hardness testing assignments. |

| DC | Extremely short impact device, other specs identical with type D. |

| Application: | Highly confined spaces. |

| Holes and cylinders. | |

| Internal measurements on assembled machines | |

| D+15 | Slim front section |

| Application: | Grooves and recessed surfaces |

| DL | Extremely slim front section. |

| Application: | Extremely confined spaces |

| Base of grooves | |

| C | Reduced impact energy (compared with type D) |

|

Application:

|

Surface hardened components, coatings |

| Minimum layer thickness: 0.2mm | |

| Thin walled or impact sensitive components (small measuring indentation) | |

| E | Synthetic diamond test tip (approx.5000 HV) |

| Application: | Extremely high hardness measurement such as high carbon steel up to 1200 HV |

| G | Enlarged test tip, increased impact energy(approx. 9 times that of type D) |

| Application: | Brinell hardness range only |

| Heavy cast and forged parts with lower demands on surface finish |

IMPACT DEVICE

Analog impact device with cable

Impact Device D

Impact Device DC

Impact Device D+15

Impact Device DL

Impact Device C

Impact Device E

Impact Device G

Universal impact device with cable

Impact Device D

Impact Device DC

Impact Device D+15

Impact Device DL

Impact Device C

Impact Device E

Impact Device G

Digital impact device with cable

Impact Device D

Wireless impact device

Impact Device D

Impact Device DC

Impact Device D+15

Impact Device DL

Impact Device C

Reading impact device

RP Reading Probe

![]()

![]()

![]()

![]()

![]()

![]()

![]()