-

Portable Hardness Tester

-

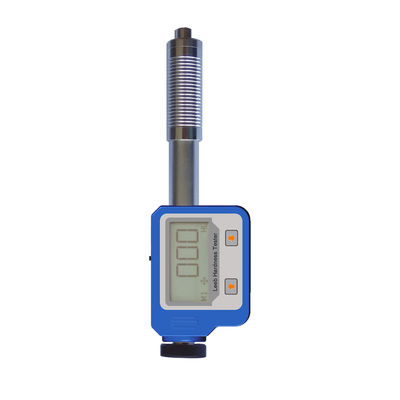

Portable Leeb Hardness Tester

-

Hardness Tester

-

Ultrasonic Thickness Gauge

-

Concrete Test Hammer

-

Brinell Hardness Testing

-

Rockwell Hardness Tester

-

Vickers Hardness Tester

-

Gloss Meter

-

Color Difference Meter

-

Metallurgical Microscope

-

Surface Roughness Tester

-

Ultrasonic Flaw Detector

-

Portable Vibration Meter

-

Paul FrameThank you very much for all your help regarding the SADT Concrete Hammer and hardness tester which are working well and we are very pleased with it.

Paul FrameThank you very much for all your help regarding the SADT Concrete Hammer and hardness tester which are working well and we are very pleased with it.

LCD Pen Type Palm Digital Portable Hardness Tester For Steel

| Place of Origin | CHINA |

|---|---|

| Brand Name | SADT |

| Certification | CE, ISO9001, SGS |

| Model Number | HARTIP1600 |

| Minimum Order Quantity | 1 |

| Price | USD200-500/Pcs |

| Packaging Details | carrying case with carton |

| Delivery Time | 2-3 days upon advanced payment for small order |

| Payment Terms | T/T, Western Union, Paypal |

| Supply Ability | 5000 pcs per year |

| Accuracy | +/-2 HLD | Memory | 999 Data |

|---|---|---|---|

| Material | 10 Metal Material | Hardness Scale | HL/HRC/HRB/HRB/HB/HV/HS/ |

| Model | HARTIP1600 | Power Supply | AAA Batteryx1(1.2-1.5) |

| Resolution | +/-0.3%@HL=800 | Warranty | 1 Year |

| Name | Leeb Hardness Tester | Probe | D Or DL |

| Highlight | palm digital portable hardness tester,palm portable hardness tester for steel,digital portable hardness tester LCD |

||

HARTIP 1600 is an advanced state-of-the-art integrated palm sized metal hardness tester which incorporate impact device and controller into one unit. Using our patent technology, SADT HARTIP1600 gives out extraordinary high accuracy up to +/-2 HL. HARTIP 1600 will be used easily by menu operation even without operation manual, also it has a customer re-calibration and statistics function.

Advantages:

Integrated design , easy operation,

Digital with high contrast LCD display,

High accuracy with patient technology: +/-2 HL (or 0.3% @HL800),

Memories with 999 data, data can be recalled easily,

USB interface, it can connect to computer ,

Customer re-calibration allowed ,

Statistics value can be calculated automatically,

With strength conversion value

|

Accuracy

|

+/-0.3% @HL=800/+-2 HLD

|

|

Materials

|

10 common metal materials Steel/Cast Steel, Alloy tool steel, Stainless steel, Grey cast Iron , Nodular cast iron, Cast aluminum, Copper-Zinc Brass, Copper aluminium, Wrought cooper, Forged steel

|

|

Memory

|

999 data

|

|

Statistics function

|

Average/Max./Min.

|

|

Display

|

LCD with back light

|

|

Recalibration

|

Allowed by user

|

|

Impact device

|

D or DL

|

|

Indicator

|

Low battery

|

|

Materials

|

10 common metal materials Steel/cast steel, Alloy tool steel, Stainless Steel, Grey cast iron, Nodular cast iron, Cast aluminum, Copper-Zinc Brass, Copper aluminium, Wrought copper, Forged steel

|

|

Measuring range

|

HL170-960/HRC1-74/HRB1.2-140/HB8-1027/HV42-1220/HS3.9-112/HRA7-88.5/89-3300N/mm2

|

|

Working environment

|

-20C~+45C

|

|

Interface

|

USB for transferring data with PC

|

|

Net weight(g)

|

105

|

|

Power supply

|

AAA battery x1(1.2~1.5V)

|

|

Dimension(mm)

|

148x45x21

|

|

Standards

|

Conforming to ASTM A956, DIN50156, GB/T17394-199

|

Requirements related to sample weight

- For samples weighing over 5 kg and of compact shape, no support is needed.

- Samples weighing between 2-5 kg, and also for heavier samples with protruding parts or thin walls, should be placed on a solid support in such a manner that they do not bend or move by the impact force.

- Samples weighing less than 2 kg should be firmly coupled with a stable support weighing over 5 kg.

- For coupling purposes,

- The coupling surface between the sample and base plate should be flat, plane parallel and ground.

- A proper thin layer of coupling paste is to be applied to the contact surface of the sample.

- The sample should be firmly pressed against the base plate surface by moving it with a circular motion.

- The direction of impact should be perpendicular to the coupling surface.

- For the coupling operation, the following prerequisites must be fulfilled:

- Contact surface between the sample and the base plate must be flat, plane parallel and ground.

- The direction of the test impact must be perpendicular to the coupled surface.

- Minimum thickness of the sample for coupling under various impact devices are shown in following tab

Range for measurement and conversion:

| IMPACT DEVICE D,DC | L D : 200-900 | ||||

| H R C | H R B | H B | H V | H S D | |

| STEEL | 20.0-67.9 | 59.6-99.5 | 80-647 | 80-940 | 32.5-99.5 |

| CWT.ST | 20.5-67.1 | 80-898 | |||

| ST.STEEL | 19.6-62.4 | 46.5-101.7 | 85-655 | 85-802 | |

| GC. IRON | 93-334 | ||||

| NC.IRON | 131-387 | ||||

| C.ALUM | 30-159 | ||||

| BRASS | 13.5-95.3 | 40-173 | |||

| BRONZE | 60-290 | ||||

| COPPER | 45-315 | ||||

![]()

![]()

![]()

![]()

![]()